During the production of distilling malt, understanding the distilling process is essential to delivering the best quality. This blog focuses on single malt distilling, as wort preparation for grain distilling is more complex.

The influence of local ingredients

Scotland’s whisky production relies on local ingredients. Barley thrives in the region’s tough growing conditions, while peat fuels kilning. Additionally, Scottish distillers use pot stills, a technique borrowed from Ireland.

Wort production for single malt whisky

Distillers use specially modified malt with a protein level below 10%. This ensures higher extract and prevents protein build-up in stills. Crushed malt mixes with hot water in the mash tun, reaching 63°C. This temperature maximises ß-amylase activity. The mash is stirred, and after 30 minutes, wort is drained by decantation.

To extract remaining sugars, distillers add hot water in three sparges, with the last at 90°C. The wort is then cooled below 30°C and transferred to the wash tun for fermentation.

Fermentation and alcohol formation

Unlike beer wort, whisky wort is not boiled. Since cooling is the only step before fermentation, amylase enzymes remain active. This process ensures that nearly all amylose and amylopectin convert into fermentable sugars.

Yeast fermentation lasts a few days, producing a wash with 10–15% alcohol. Distillers often use a combination of proprietary yeast and brewing or baking yeast.

| Duration 4 – 7 h. | Wash tun | Low wines |

| Alcohol concentration | 10% | 26% |

| Volume reduction | 100% | 37% |

The distillation process

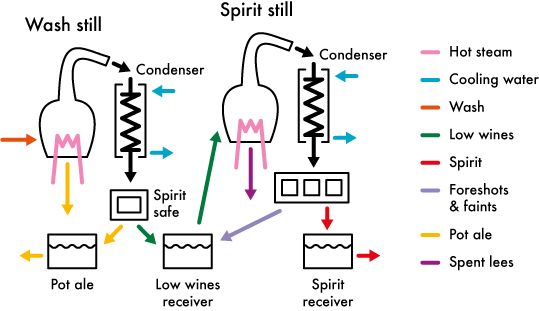

Alcohol concentration requires at least two distillations. The first stage reduces volume and concentrates alcohol while removing heavy fusel oils. Next, purification occurs in the spirit still. British law mandates that all pipes and pot stills remain padlocked, preventing direct tasting. Instead, distillers monitor the spirit safe to assess quality.

Separating the middle cut

Only a specific window of the distilling process produces spirit suitable for maturation. At the start, foreshots contain unwanted aldehydes. The middle cut is the desired crude spirit, while fusel oils evaporate at the end. Both foreshots and fusel oils return to the low wines receiver for reprocessing.

Careful and slow distillation prevents fusel oil transfer to the middle cut. Once distillation is complete, raw spirit matures in wooden casks. To qualify as whisky, the spirit must age for at least three years. The cask influences both colour and aroma.

| Duration 3 h. (middle cut) | Low wines | Raw spirit |

| Alcohol concentration | 26% | 67,5% |

| Volume reduction | 37% | 14% |

The role of peat and casks

Sherry and bourbon casks are popular choices for maturation. However, the final whisky profile depends on several factors. Peat levels, still shape, cask type, and phenol content all play crucial roles. Low-peated whiskies contain 0–3 ppm phenol, while heavily peated varieties exceed 30 ppm.

Safety and barley selection

Distilling alcohol requires care, especially when using copper stills. In the past, some barley varieties produced dangerous cyanides. Once discovered forty years ago, the whisky industry switched to safer barley strains. Today, Laureate, Concerto, and Odyssey remain top choices, excelling in both brewing and distilling.

Craft distilling and speciality malts

Craft distillers use a variety of equipment, depending on the spirit. Small-scale installations often produce clean spirits like gin and vodka or more aromatic ones like jenever and whisky. Many distillers appreciate speciality malts for their unique flavours.

Pot stills vs column stills

Column stills can produce nearly pure alcohol (96%) in one continuous process. In contrast, pot stills operate in batches, achieving 70% alcohol at best. Pot still advocates argue that their method creates more aromatic spirits, making distilling malt selection even more critical. However, regardless of the still type, it is ultimately the distiller’s skill in making cuts that defines the final spirit.

The production of distilling malt plays a crucial role in whisky-making. From wort preparation to fermentation and careful distillation, every step impacts the final spirit. Whether using pot stills or column stills, distillers rely on high-quality malt to create exceptional whisky. By understanding the process, malt producers can continue to support both traditional and craft distillers in achieving the best possible results.