Craft brewing focuses on one key goal: creating the best-tasting beers. Craft brewers spend countless hours selecting top-quality ingredients and fine-tuning their brewery setup to achieve the perfect flavour. However, this dedication often comes at the cost of time, money, and efficiency. In this article, we explore what lowers brewhouse efficiency and how to improve it.

Why does efficiency matter? Craft brewing is an art, but it’s also a business. Making small adjustments can save significant money over time. Improving efficiency from 75% to 85% in a 1,000-litre system saves one bag of malt per brew. Moreover, a more efficient brewhouse reduces energy and water usage. Being inefficient is not the same as being crafty!

Defining brewhouse efficiency

Brewhouse efficiency measures how much of the potential fermentables make it into the wort, based on gravity and volume. This figure, often called efficiency into the boiler, differs from efficiency into the fermenter, which accounts for hop absorption and transfer losses. The key is consistency—use the same measurement every time to track improvements and compare results.

Determining brewhouse efficiency

Most craft brewers rely on brewing software like Beersmith or ProMash to calculate efficiencies at different process stages. However, understanding the underlying formula is crucial.

- Brewhouse efficiency = actual grain extract / potential grain extract

- Actual grain extract = wort volume in l * specific gravity in sg * Plato / 100

- Potential grain extract = weight of grist in kg * fine grind extract %

To determine actual grain extract, multiply wort volume by its specific gravity to get the wort’s weight. Then, multiply this by the wort strength in Plato, which indicates how much of the wort consists of extract. Always correct volume measurements for temperature, as heat causes expansion.

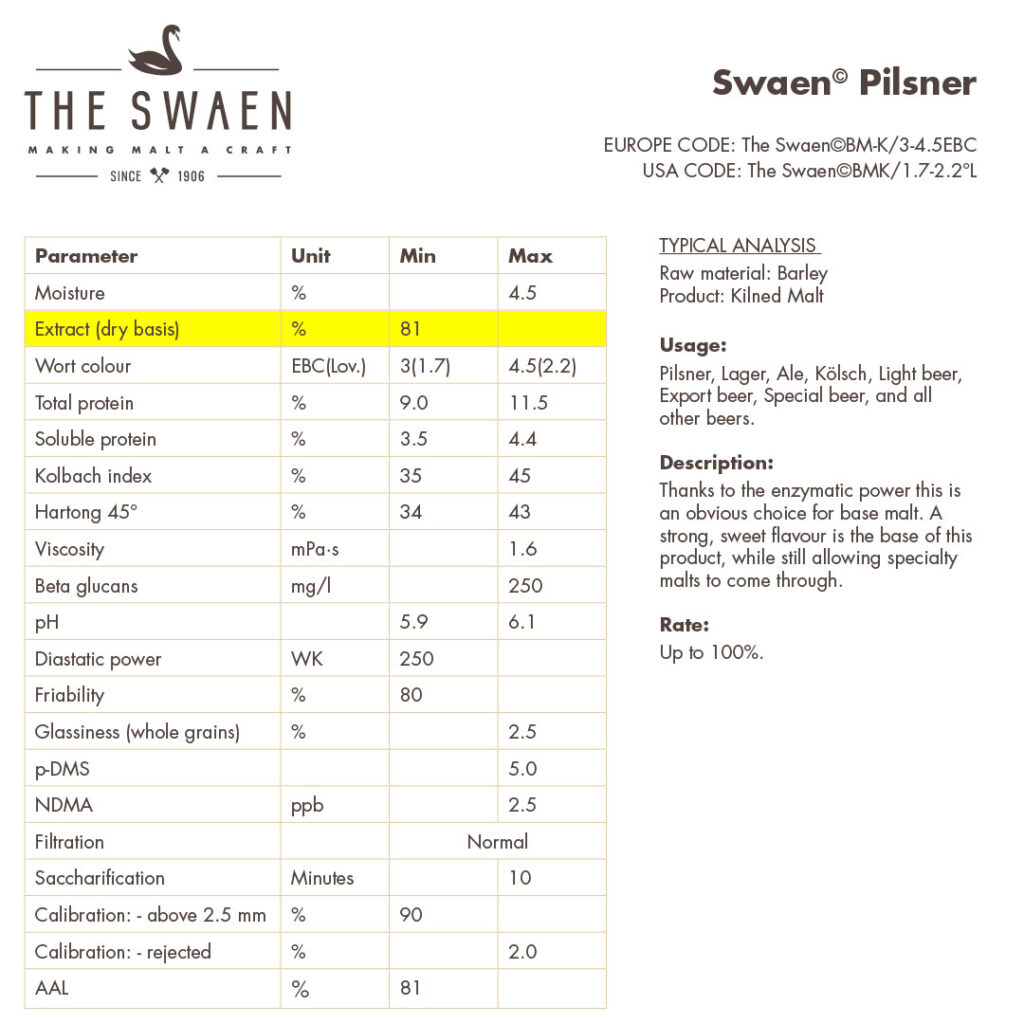

Potential grain extract represents the extractable weight from the grist. Brewers can find this figure on the malt analysis. Malt extract content is given as a percentage of dry weight, but since malt contains 3-5% moisture, adjustments are necessary: (100% – MC)/100%.

Several factors affect efficiency calculations. Measurement errors in gravity, volume, or weight impact results. For instance, a 5% grain weight error (10kg in a 200kg grist) causes a 5% efficiency variance. A reported 70% efficiency might actually range from 66% to 74%.

The following measurement errors can be seen as reasonable:

- 1% error for the grain weight (0.1kg on 10kg).

- 2% error for the specific gravity or wort strength (0.25 on 12P).

- 2% error on the volume measurement. This means (10l on 500l).

- Combined the efficiency can be calculated with 5% accuracy.

How good is my efficiency?

Once brewers calculate efficiency, they can compare it to industry standards. Opinions vary, but efficiency depends on many factors. The following table provides typical brewhouse efficiency ranges for different brewing systems. These figures reflect efficiencies measured in the boil kettle, not the fermenter.

| Brewing system | Typical brewhouse efficiency range |

| Large-scale commercial brewing | 92% – 100% |

| Fly sparging | 80% – 95% |

| Batch sparging | 75% – 90% |

| No sparge | 65% – 80% |

Boosting brewhouse efficiency

Now comes the exciting part—improving efficiency. Three key processes impact brewhouse efficiency: milling, mashing, and lautering. Ingredient quality also plays a crucial role. Let’s break them down.

1. Quality malt

Superior malt boosts efficiency. The best malts come from European two-row spring barley, carefully selected for kernel size. At least 95% of kernels exceed 2.5mm, ensuring better milling and a higher starch-to-husk ratio.

Extract levels matter, but efficiency isn’t just about extract content. Brewers must focus on the difference between fine and coarse grind extract levels. This gap should be under 1%, yet in some cases, it exceeds 3%. That 3% loss directly reduces efficiency.

Friability also affects efficiency. High-friability malts break down easily during milling, ensuring better starch access. Another factor is diastatic power—the malt’s enzymatic strength. More enzymes mean better starch conversion, but too much can create inconsistent outcomes for all-malt brewers.

Protein levels also impact efficiency. High protein content makes modification harder and can hinder lautering by forming dense protein layers over the grain bed.

2. Milling

Even with high-quality malt, poor milling lowers efficiency. Regularly inspect milling results. Are some kernels uncrushed? Do cracked kernels fail to release their endosperm?

Good milling separates the inner meal from the husk without producing excessive flour. Over-milling generates too much flour, tightening the filter bed and slowing lautering. If efficiency drops and excess flour appears, try a coarser grind. On the other hand, large, unbroken kernels indicate a grind that’s too coarse, low friability, or under-modified malt. Striking the right balance ensures efficient conversion and easy lautering.

3. Mash parameters

Mash temperatures between 63°C and 80°C fully convert starches. The ideal saccharification temperature depends on mash schedules, rest times, attenuation goals, and diastatic power. While mash temperature affects beer flavour, it has little impact on efficiency.

However, mash pH significantly influences efficiency. Studies show that an optimal pH of 5.5 to 5.6 maximises conversion. Deviations of just 0.2 from this range can lower brewhouse efficiency by 2%.

4. Lauter efficiency

Lautering aims to extract maximum fermentables from the grain. Lauter speed and efficiency depend on the grain bed. Unbroken husks create a looser bed, allowing quicker run-off. Keeping mash stirring minimal and avoiding over-milling also prevents lautering issues.

Start lautering slowly, then gradually increase the speed to avoid channeling. Grain volume and pre-boil volume also impact efficiency. A higher grain-to-batch-size ratio traps more wort in the spent grain, reducing efficiency. While increasing sparge water recovers more extract, it raises pre-boil volume, extending boil times and increasing energy costs. Excessive sparging may also harm beer quality, so it’s not a solution for poor efficiency.

Final thoughts

Low efficiency signals process issues, but extremely high efficiency doesn’t guarantee great beer. Brewers must balance beer quality, brewhouse efficiency, and energy use. By refining malt selection, milling, mashing, and lautering, brewers can optimise efficiency without compromising flavour. A well-balanced approach ensures both great beer and a more sustainable brewing process.